Dual Systems offer more opportunities

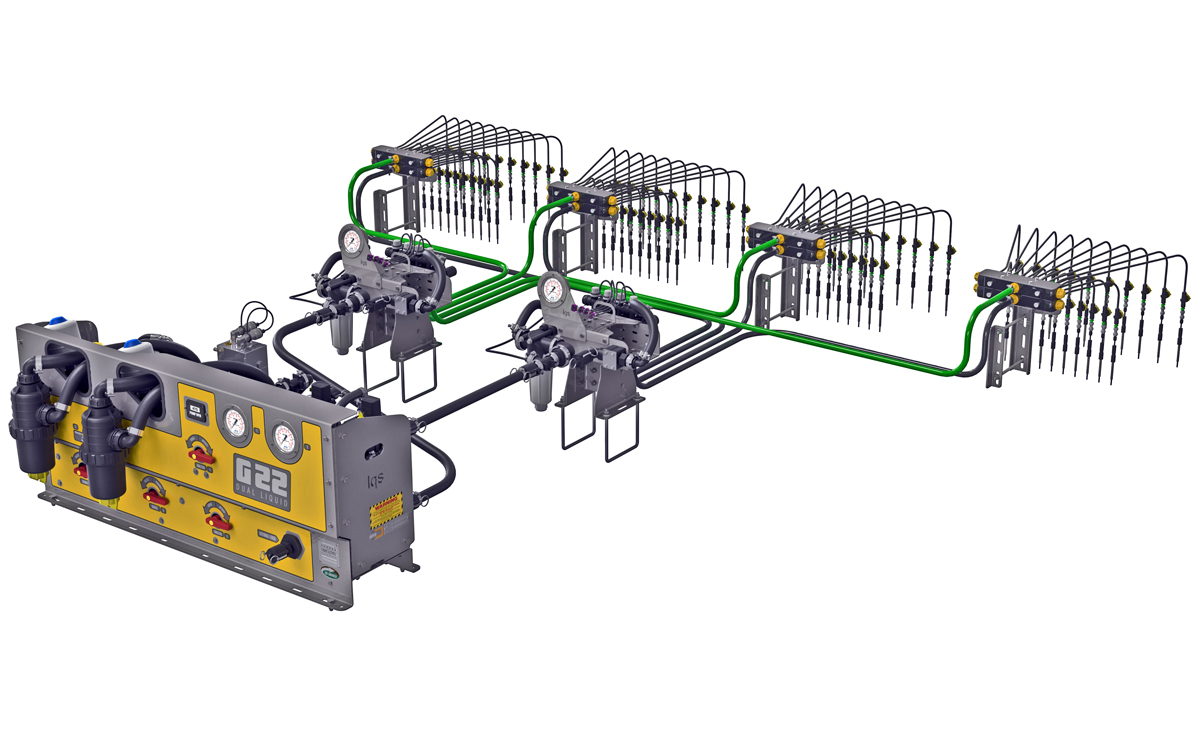

Pictured above: G22 Pump & Control Module is state of the art Dual liquid auto-rate system integrated with the Dual 4 Section Control (valve banks) Stacker Distribution Kit.

The G22 gives the farmer the ability to apply two separate liquids with full independent rate control. Its high capacity pumps provide the means to deliver higher application rates or provide additional tank agitation. The second pump can be switched off for single liquid application mode.

Dual Liquid retrofitted onto a Seed Hawk 84″ Tool Bar. Symmetry of the rig is centred around the powerful Dual G-22 (180 Upgrade) Pump and Control module integrated with Dual 8 X Section Swath Control STACKER Distribution System Kit featuring FIBP (LQS-ATFB) terminals, split application and a host of other options and enhancements.

Dual Systems are typically used when incompatible nutrients are being applied in-furrow. For instance, many products do not like being mixed with APP. Oxides and sulphates can have compatibility issues with UAN whereas chelates are usually quite OK. Zinc has a propensity to build-up within systems, especially with certain carriers so alternative carriers must be utilised.

Dual Systems help overcome a multitude of incompatibility problems due to carrier options. For example you may wish to apply a starter but find that an inoculant or fungicide is incompatible. Quite often operators will opt to utilise water as the second liquid carrier for applying difficult to manage products.

Some operators utilise Dual Systems for in-furrow and inter-furrow application. For example with FMFO’s on row crop planters.

Liquid Section Control is becoming even more popular on air seeder tool bars since the introduction of air shut-off to the seed distribution heads (section control of seed application). Efficiencies are multiplied, no overlaps for seed or liquid products in-furrow application.

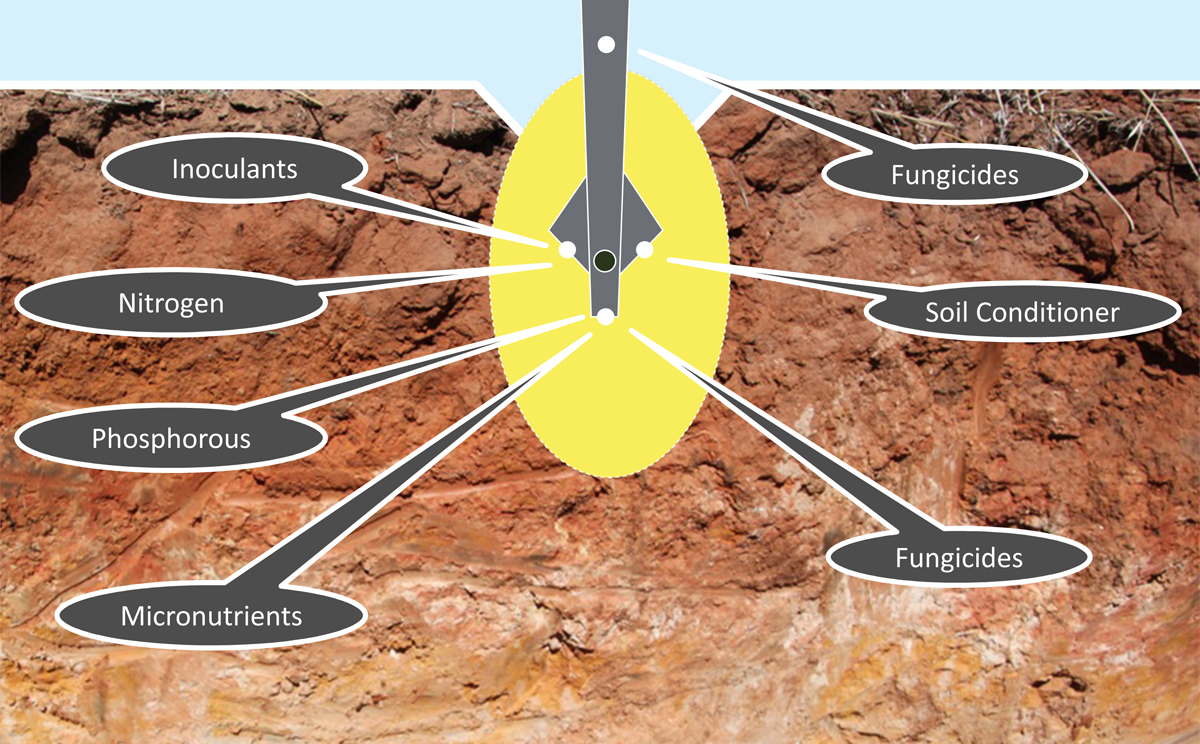

Dual Systems combined with our Dual “Stacker Distribution Kits” also step up the options for growers with multiple liquids in one pass at different levels within the soil horizon.

Our Dual Auto- Rate Systems integrated with our Dual “Stacker Distribution Kits” allow multiple liquids to be applied at varying soil depths in one pass.

With our systems you can do deep banding, side banding, banding with seed, surface banding all at different horizons and all with independent rate control of multiple liquid streams, allowing separate injection of incompatible products and where necessary separation of seed from liquid products.

For example, Nitrogen can be side banded, soil conditioning agents can be deep banded and starter fertilizer can be added precisely with the seed higher up in the profile.

Flutriofol can be applied on and with the seed and split ratio applied on the surface in conjunction with in-furrow application to combat Rhizoctonia!

As people are becoming more confident and familiar with our systems and with in-furrow liquid application, more and more people are looking towards our Dual Systems.

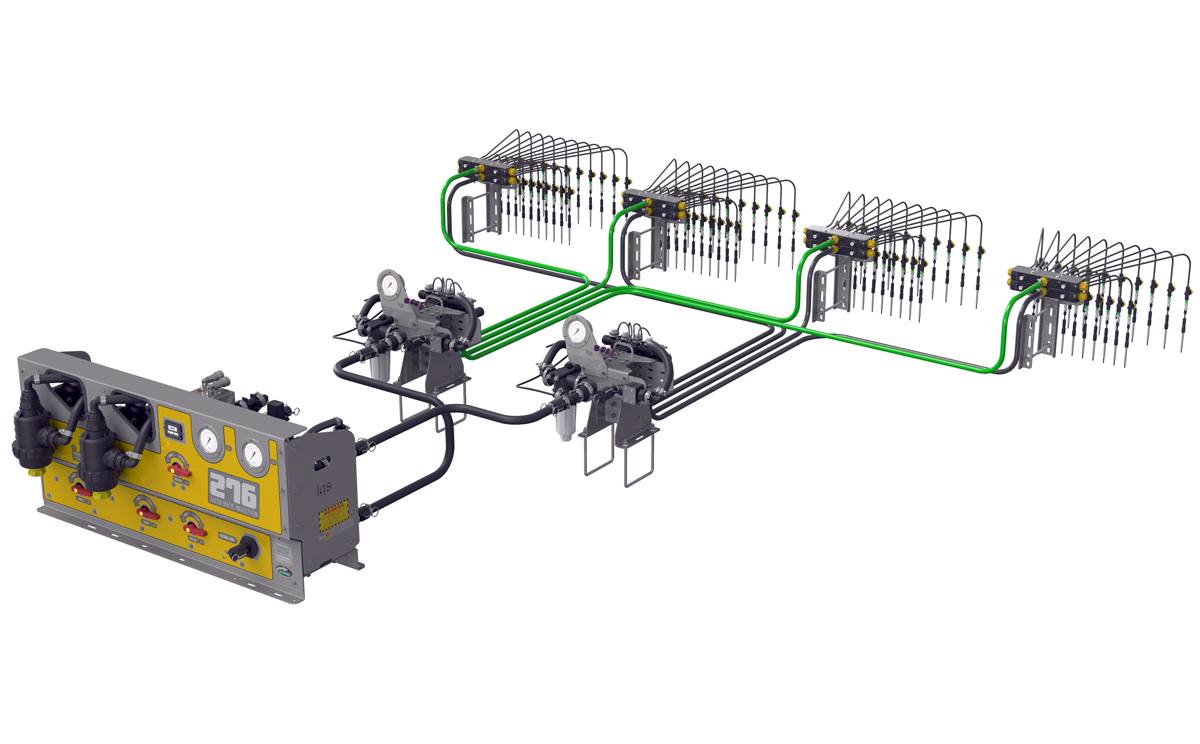

We have two Dual Modules, the G22 Module and the 276 Module:

- Our systems are engineered for true & proven rate control

- Every system is Wet Tested before it leaves the factory floor, ready to go anywhere in the world.

- All systems are Precision Ag Integrated with our own wiring looms, ready for variable rate plug & play with leading brand controllers (Greenstar / Trimble / Topcon / Ag Leader etc.).

- They are easy to install and retro fit onto any colour implement.

- All systems have documented configurations for easy diagnostics and servicing.

- All systems are compatible with our Stacker Distribution Kits

Features:

- Stainless Steel Module construction and Pump enhancement.

- Provide tank agitation for keeping chemicals in tank in solution and mixed.

- Have the ability to vary rates on the go.

- Our pumps are self-priming.

- Our pumps are able to run dry without damage.

- Our pumps do not cavitate and boil liquids & do not destroy the very product they are delivering.

- Provide pulse free delivery.

- System fail-safes for over-speed and over-pressure.

- Clean water purging function to flush chemicals out of delivery lines during stoppages.

- Section (Swath) Control options.

- Static testing & calibration provide means to verify accuracy of rate control system before operation.

Customer Case Studies:

1) READ THE FULL STORY HERE – Queensland customer – 276 Dual Rate Control Module mounted on his Boss AG Supa-Flex

2) READ THE FULL STORY HERE – Victorian customer – G22 Dual Rate Control Module mounted on an Ausplow liquid cart.

Get a Quote

"*" indicates required fields