Stacker Distribution Kits

What is a “Stacker” Kit?

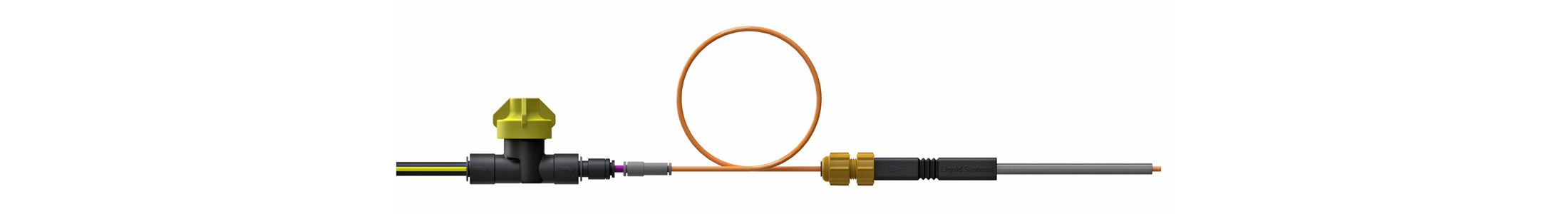

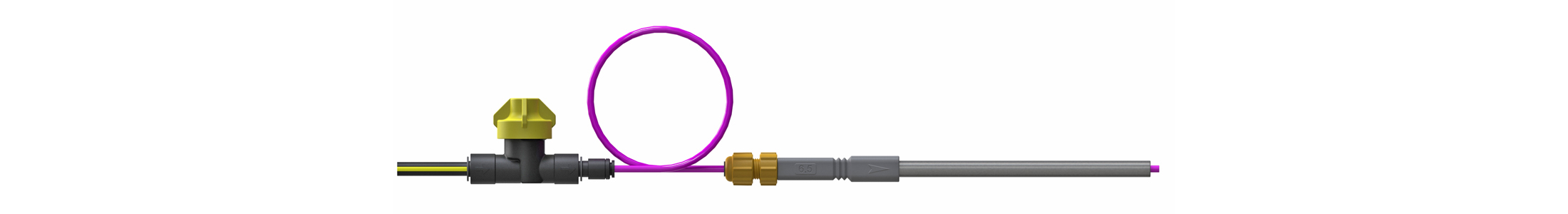

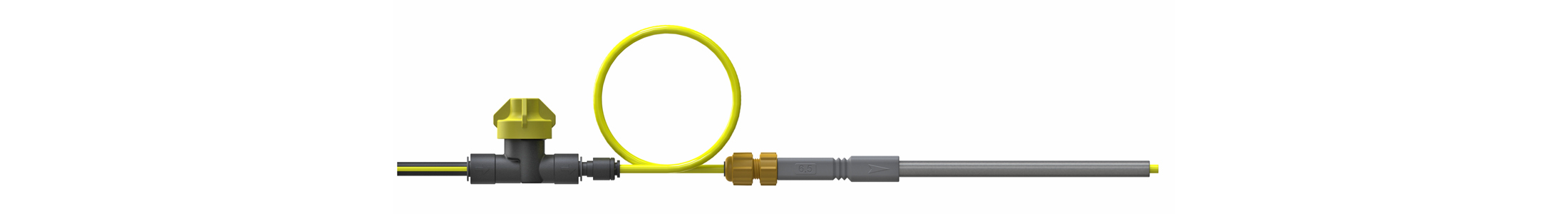

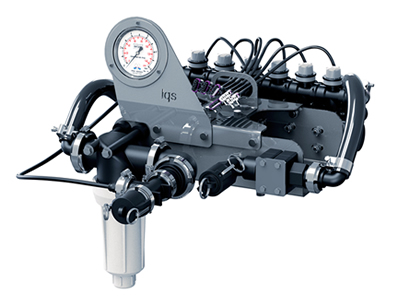

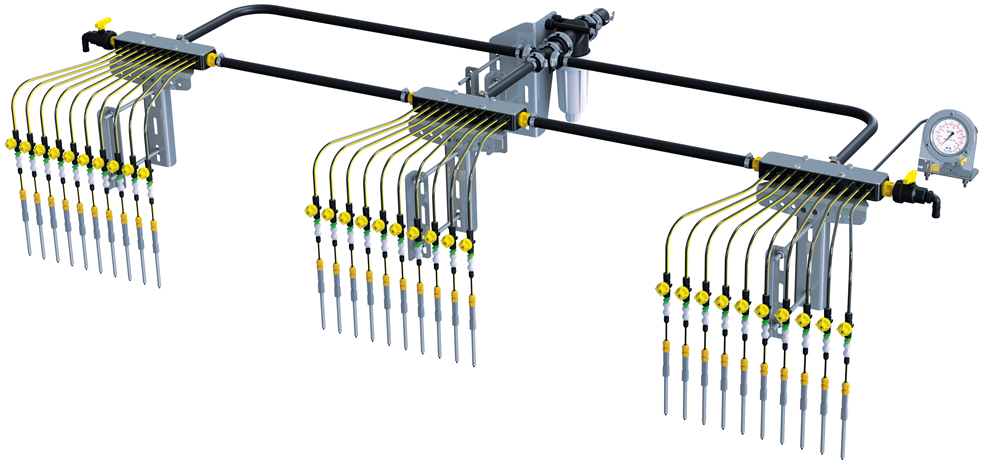

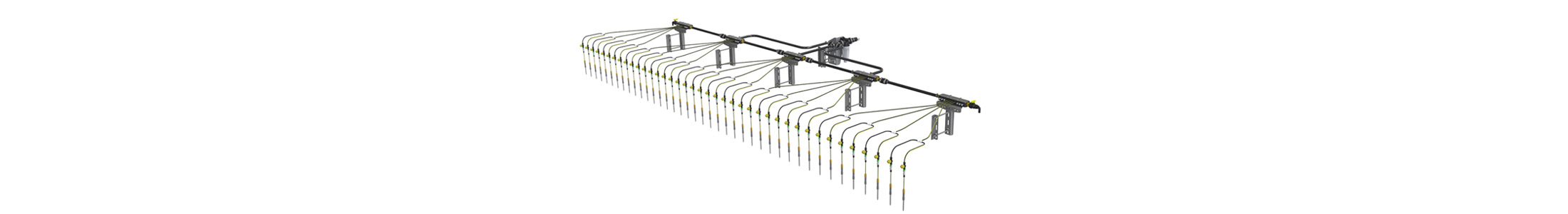

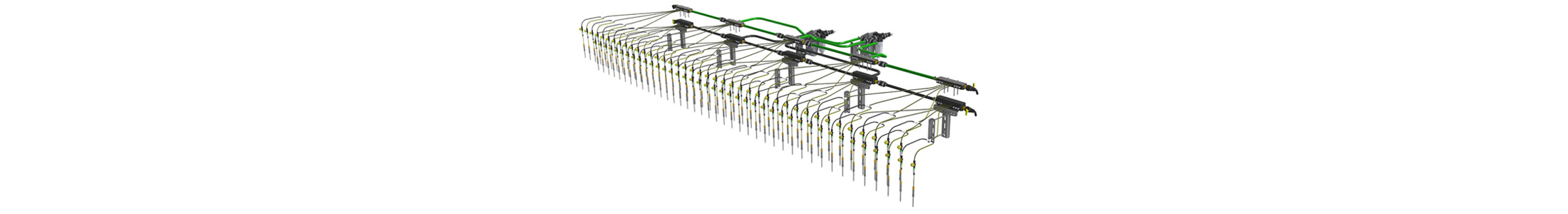

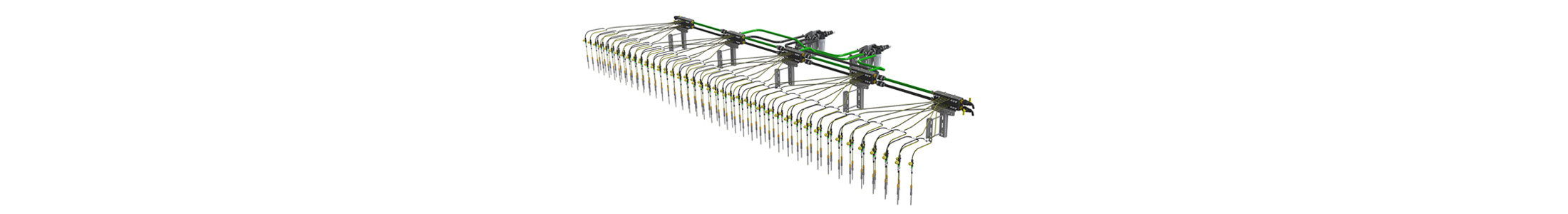

The “Stacker” Kit is an integral part of our Liquid Systems. It provides custom components and plumbing to deliver/distribute liquid products in-furrow. The “Stacker” Kit is engineered to deliver the liquid product under controlled positive pressure all the way to the opener terminals with row to row accuracy and even distribution.

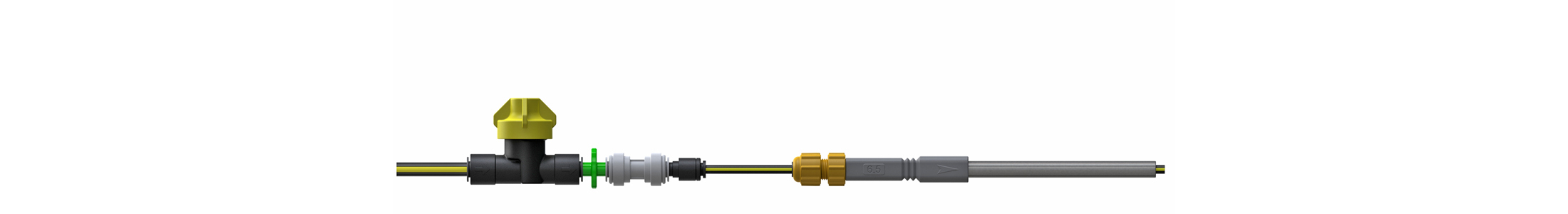

The manifold is the core of the “Stacker” Kit. The manifold has been designed for multiple stacking and interconnects to gives the customer total flexibility for system installation on any size tillage bars and planters. The stacking manifold enables independent multiple liquids in one pass.

The “Stacker” Kit comes complete with everything needed for any bar width, including a range of terminal assemblies to suit different openers, application rates, products & row spacing.

Touch the crosses to learn more about the STACKER KIT

LEARN MORE HERE »

MANIFOLD O’RING ADAPTORS have been designed to eliminate leaks & issues that can arise when trying to maintain a seal on threaded fittings. Thread sealants are not required.

LEARN MORE HERE »

LEARN MORE HERE »

LEARN MORE HERE »

FLEXIBLE KIT DESIGN offers so much choice and is so simple to modify or upgrade. Choose Section Control, Single Swath or Dual Swath.

SECTION CONTROL is available as an option with any LQS System. It provides enormous efficiency gains through reduced overlap. Section valves are driven by Precision Ag controllers. Each section connects to a separate “STACKER” Manifold which are available in a variety of configurations for varying planting regimes. Implement up to 12 sections on planters and air seeders.

LEARN MORE HERE »

LEARN MORE HERE »

FEATURES

- Unique LQS custom-designed components for controlled liquid delivery.

- Push-in fittings for easier installation & maintenance.

- Robust, high quality, chemical resistant components.

- Incorporates appropriate filtration.

- Universal stainless steel mounting brackets allow fitting to any planting or tillage implement.

- Range of terminal assemblies to suit different openers, application rates & products.

BENEFITS

- Proven row-to-row accuracy to optimize efficiency of liquid products.

- Targeted nutrient placement – every seed to get it fair share.

- Even distribution down to very low application rates.

- Flexibility to work over a wide range of application rates, number of outlets and operating speeds.

- Controlled positive liquid pressure to prevent outlet blockages.

- Instantaneous start-up and shutdown at the headlands.

- The ability to apply multiple liquids in one pass.

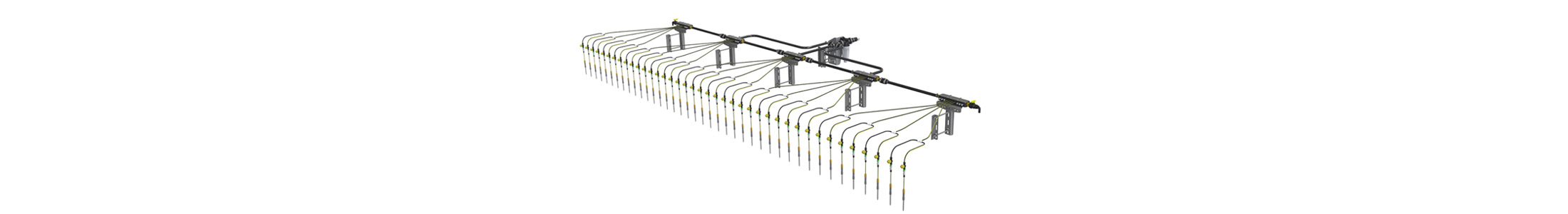

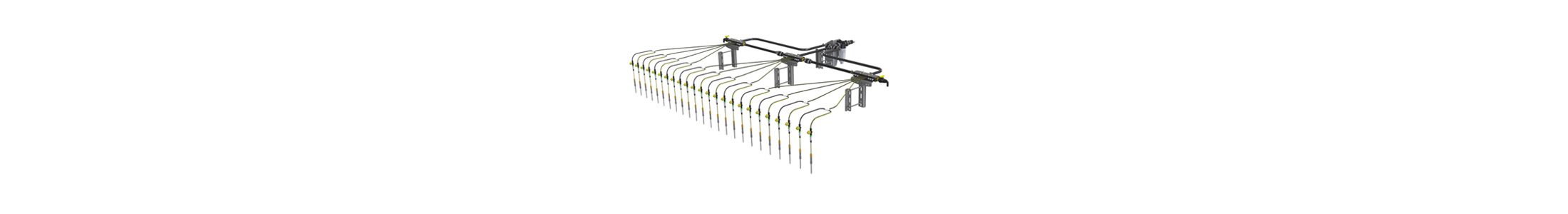

SINGLE LIQUID

MANIFOLD CONFIGURATIONS

TO SUIT ANY SIZE BAR

QLD growers switched from homemade parts to LQS Systems

Ross and Mitch Faint upgraded to Liquid Systems (SA) equipment, eliminating costly down-time caused by their self-built set-up. Super impressed with the increased efficiency gained and love the accuracy it’s delivering.

row to row accuracy counts

Accurate and even distribution of inputs is critical for crop protection success. With the ability to target inputs exactly where you want them and at the correct rates is all about the farmer maximising the benefits of their inputs.

The stacker distribution system is my favourite part because the product is always distributed evenly, right across the bar. I don’t see rows further out getting less liquid or those closer in getting more.

Sam Kelly, New South WalesI needed to have a constant rate of crop protectant of fungicide and zinc products,

along with handling and safety issues, the Liquid Systems unit proved to be very

reliable, very easy to use and calibrate and paid for itself in the first season by not having to apply any post-seeding applications of crop care products.

Trevor Walters, VictoriaIt’s a technically superior system, there’s no doubt about that, It changed the profitability of our farm dramatically.

Andrew Polkinghorne, South AustraliaThe system was beautifully presented, very easy to install & worked brilliantly.

Ross Fisicaro, New South Wales

Get a Quote

"*" indicates required fields