Reflecting on 20 years of boosting crop performance

Never in his wildest dreams did mechanical engineer Peter Burgess imagine an interest in liquid fertilizer research would set him on a path to building a company that sells precision application systems around the world.

Mr Burgess was working with Aussie Ag in the late 1990s, when he learned scientists at the Minnipa Agricultural Centre (MAC) had found a way to improve the uptake of phosphorus and trace elements by cereal crops grown on the Eyre Peninsula’s highly calcareous and alkaline soils.

The researchers found fluid fertilizer mixes, using ingredients such as phosphoric acid, could be five times as effective as equivalent rates of granular fertilizers. Dr Bob Holloway OAM, who managed the MAC from 1977 to 2006, recalled they had been using very primitive equipment at the time.

“It was enough to prove a concept but not suitable for industrial use in Australia,” he said. “Peter expressed interest in what we were doing, and everything changed.”

Working out of his garage, Mr Burgess started by adapting boom spray technology.

And as farmers across Australia took an interest in fluid fertilizers, Mr Burgess began designing and building systems capable of accurately delivering corrosive liquids like phosphoric acid.

“I could see the potential of in-furrow liquid application,” he said. “But it couldn’t be done effectively with off-the-shelf components. My aim was to design and manufacture ‘built for purpose’ equipment that could deliver reliable and verifiable rates of liquids in-furrow in the harshest of conditions.”

After doing the rounds of field days with his first prototypes, Mr Burgess founded Liquid Systems (SA) in 2002.

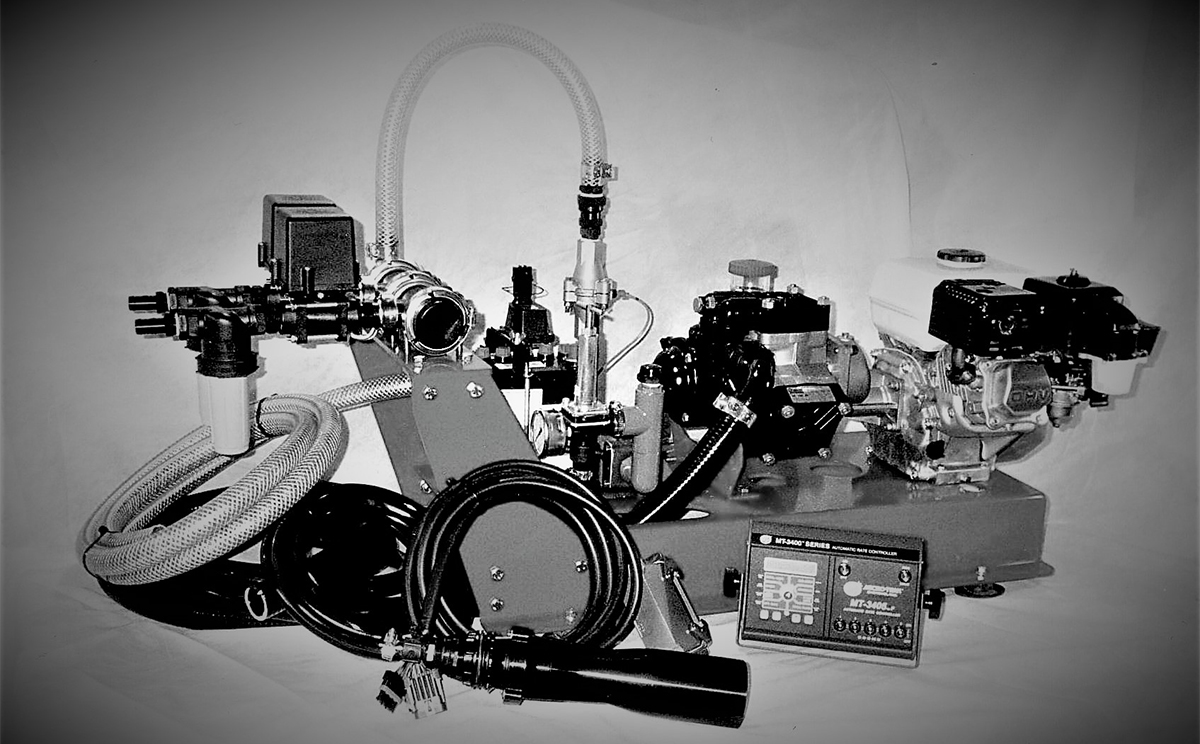

Image Below: One of the first Liquid Systems in 1999.

Perth company McIntosh Distribution approached Mr Burgess at a CSBP field day in Brookton, Western Australia, to collaborate on a liquid kit that could be factory-fitted to its Morris air carts. This was the beginning of a mutual innovative partnership that has evolved to become one of the most recognised liquid ready air carts in the Australian market today.

Danny Sanderson, who farms at Grass Patch and Varley in WA, was one of the first grain growers to adopt fluid fertilizers, adding an early Liquid Systems a-i module to his Morris 8425 Series air cart in 2004. Mr Sanderson upgraded to a GEN4 system in 2015, which he uses for injecting UAN, zinc and flutriafol in a single pass.

“Liquid Systems make a good product. It’s saving the cost of the boom spray, but it’s more about the efficiency of the nitrogen,” he said. “The best place for nitrogen to be is banded in the ground where it can’t volatilise and disappear, so we find our nitrogen use is very, very efficient.”

Mr Burgess worked closely with early adopters and enthusiasts to explore ways to refine the designs, cater for multiple products, and develop the signature Stacker Distribution Kit suitable for machines of any size.

Image Below: Danny Sanderson’s first Liquid Systems a-i Module on his Morris 8425 Series air cart in 2004.

Image Below: Danny Sanderson today with his 2015 Morris Liquid Air Cart and Liquid Systems’ GEN4 Pump Module

A partnership with John Deere, in 2010 helped Mr Burgess gain a foothold overseas with Liquid Ready Kits for the John Deere 1910 Air Commodity Cart and John Deere C650 Air Cart.

Since then, Liquid Systems (SA) has grown, expanding its workforce, moving to a new factory in 2019 and exporting its products to grain and row crop farmers using equipment “of any colour” in the United States, Canada, Russia, Bulgaria, and Poland.

“Over the years we have learnt so much,” Mr Burgess said. “I am incredibly proud of our team and grateful for their commitment and professionalism. We will continue to partner with farmers to improve our equipment and help them be more efficient with inputs and their time.”

Image Below: Liquid Systems (SA) Dealer fit “Liquid Ready Fert Kit” on the John Deere TBT & TBH C650 Air Carts.