Reliable liquid delivery systems that optimise every pass across the paddock.

LQS-Range-2200x500_series

LQS-Range-2200x500_dual

UPGRADE TO A MULTISYSTEM WHEN YOU ARE READY!

Multiple liquids in one pass. Tackles more soil issues at the same time.

LQS-Range-2200x500_morris_homelight

LQS-Range-2200x500_dual_home

LQS-Range-2200x500_series

Reliable liquid delivery systems that optimise every pass across the paddock.

LQS-Range-2200x500_dual

UPGRADE TO A MULTISYSTEM WHEN YOU ARE READY!

Multiple liquids in one pass. Tackles more soil issues at the same time.

LQS-Range-2200x500_morris_homelight

LQS-Range-2200x500_dual_home

Revolutionize Your Farm with Precision Liquid Delivery Systems

Since 2002, Liquid Systems (SA) has been at the forefront of manufacturing reliable and precise liquid delivery systems for planters and seeders worldwide. Our state-of-the-art equipment is designed for the accurate in-furrow injection of liquid fertilizers, fungicides, insecticides, nematicides, micronutrients, inoculants, soil conditioners, and soil wetters.

Our in-furrow application equipment helps farmers increase soil productivity, boost yields, and save on inputs, providing the intelligence needed to maximize profitability. Our versatile product range easily retrofits onto any size or colour implement, offering unmatched flexibility and accurate rate control for nutrient application, whether for sub-surface in-furrow delivery or pressurized surface banding of liquid nutrients and crop care products.

Transform your farming operations with Liquid Systems (SA) and experience the benefits of precision, efficiency, and reliability.

Touch the crosses to learn more about OUR LIQUID DELIVERY SYSTEMS

PRECISION AG INTEGRATION with all Liquid Systems Modules is simply plug’n’play with a wide range of leading Precision Ag Consoles.

LEARN MORE HERE »

LEARN MORE HERE »

*OPTION: LIQUID SECTION CONTROL KIT “Stacker“ Section Control configurations deliver enormous efficiency gains in both land use and liquid product application through better coverage and reduced overlap - particularly with irregular paddock shapes.

LEARN MORE HERE »

LEARN MORE HERE »

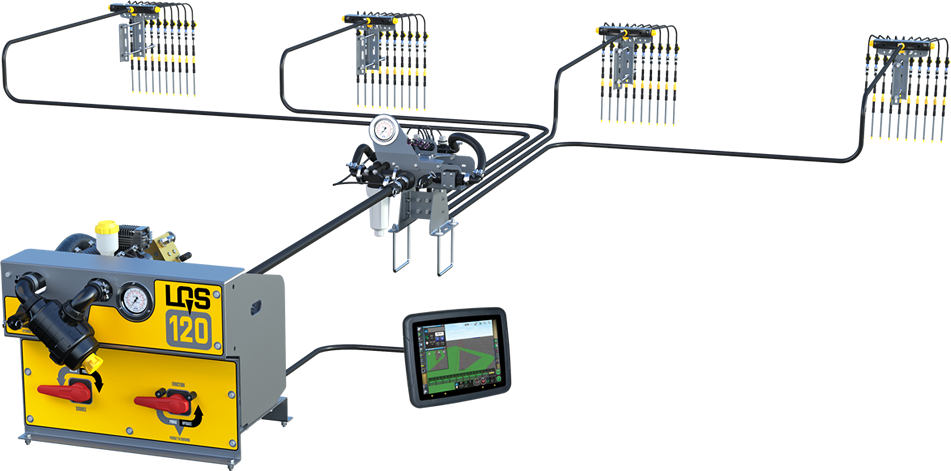

LQS RATE CONTROL MODULES are engineered to provide accurate target rate application, while maintaining the physical integrity of liquid products in super tough conditions. All modules upgrade easily to a Dual/Multi Systems and can add Section Control at any time. Fast shut-off, reliable, accurate in-furrow delivery.

LEARN MORE HERE »

LEARN MORE HERE »

“STACKER” DISTRIBUTION KIT provides even and accurate liquid delivery into the furrow. Every component including the “STACKER” Manifold has been designed to deliver product under controlled positive pressure all the way to the opener.

LEARN MORE HERE »

LEARN MORE HERE »

CUSTOMER CASE STUDIES

Satisfied customers share their experiences and stories about transitioning to liquids with Liquid Systems (SA) Equipment. All customers have unique set ups, different soil conditions & different nutrient requirements. Let them inspire & assist your research process of in-furrow liquid application.

Ultimate variable rate flexibility

All Rate Control Modules can be integrated with a wide range of leading Precision Ag Consoles. Liquid Systems (SA) provides a range of custom adaptor harnesses to provide simple Plug’n’Play integration.

Multiple liquids one pass

All modules integrate seamlessly with our ‘STACKER DISTRIBUTION KIT’ for a complete Liquid Ready Kit. All you need to do is to decide what you want to do! Our systems can be used for subsurface in-furrow application or pressurised surface banding of liquid nutrients and crop care products. We’ll help configure want you need.

We’re finding the plants are healthier and booming out of the ground because, with liquid delivery, all the fertiliser, fungicide and trace elements we are applying are available to the crop. We haven’t had any hiccups with the Liquid Systems gear and Peter Burgess’s back up and support has been brilliant.

Matt Price, Cleve, SA‘’I apply inoculant using the Liquid System at planting and not only am I coating the seed but I’m inoculating my ground as well. This gives the seed the most perfect little world to germinate in and it works remarkably well. I can’t describe how happy I am about that part of the system – it just works so well.’’

‘’I’m not aware of any other system in Australia that can do it as accurately.’’Lee Lonergan, Mungindi NSWWe got two liquid fertiliser systems on it so we can put the liquid UAN (urea & ammonium nitrate) down in front on rows away from the corn, he said. We put it down away from the seed. That lets you put higher rates of fertiliser down all in the one go and not burn the seed. We can also put down the Starter right at the seed to kick the seed along before it comes up. It is all on one monitor in the cab so the whole operation is pretty simple. All the liquid control system is on the one screen.

Matt Young, Farm Manager, QLD“I needed to have a constant rate of crop protectant of fungicide and zinc products, along with handling and safety issues, the Liquid Systems unit proved to be very reliable, very easy to use and calibrate and paid for itself in the first season by not having to apply any post cropping applications of crop care products.”

Trevor Walters, Manangatang VIC.We have had excellent luck with your system through Spring 2014 planting and will begin Fall 2014 planting in the coming weeks.

Seth Millhorn , Idaho, USA“We’ve had some pretty low rainfall years, and we can justify the system as we’ve had some pretty good crops in those years – it all comes back to the technology and the liquid system we’re using.”

Leeton Ryan, Winnambool VIC.The system was beautifully presented, very easy to install & worked brilliantly.

Ross Fisicaro, Warragoon, N.S.W“I’m rapt with this set up — I said to someone the other day I can’t wait for seeding time next year as this system is so good to use.” “We have soil that’s low in trace elements and the plant is taking up all the nutrients we are putting out.” He said. “We have had to change the way we farm but we are heading down the right track without a doubt.”

Paul Lush, Mallala S.A.“I’m very happy with the performance of our a-i and the support provided by Liquid Systems (SA). I’m particularly impressed with the quality of their products.”

Andrew Longmire, Salmon Gums W.A.“I used the dual pump system this year with very pleasing results. I put liquid nitrogen and some phosphate over 4000Ha and found this system very accurate, reliable and able to stand up to all I asked of it.”

Paul Smith, Mukinbudin W.A.“Liquid Systems has made an enormous contribution to the development of the fluid fertiliser industry in Australia and continues to do so.”

Dr Bob Holloway , OAMThis season we purchased a VRS system for our small plot seeder. After a few modifications (we needed to run the system off a hydropak motor as our seeder is a ute trailed machone) everything went ultra smooth. The team at LQS SA were very helpful in getting us up and running and in helping us calibrate the machine. We used a range of line meters with a number of different products, from UAN, APP, liquid dolomite and limes and a huge range of trace elements, ranging from 30-60L/ha. We found the 60L tank very useful as when banding UAN @ 50L over 250 plots we needed some volume. Also we found the minimum batch usually would be around 6-10L as the lines generally hold a minimum of 3L. All in all I couldn’t recommend a better trial system or overall liquid system (I also run a full Liquid Systems kit on our primaries bar on the family farm). Thanks again Peter and the team

Leigh Nairn, Northampton Agri ServicesThis is just another phase in the journey of a company with exceptional products.

John Henchy, EO, Farm Machinery & Industry Association of WA