LQS Module Range

Precision Ag Revolution: Simplified Liquid Delivery with LQS Systems

Since 2002, we have been at the forefront of Precision Ag Liquid Delivery Systems, providing targeted liquid input applications with accurate rates and consistent, even placement in the furrow.

Our LQS range is engineered to offer simpler, more flexible, and better-supported systems, all while maintaining the reliability and accuracy our customers expect and deserve. Fixed module configurations enhance portability, servicing, and troubleshooting, ensuring seamless upgrades to duals with separate liquids and section control.

With plug-and-play integration, connecting to all leading Precision Ag Displays and Controllers is effortless using off-the-shelf adaptor looms. We also offer a range of ISOBus control options for ultimate compatibility.

Complete your system with a “Stacker” Distribution Kit, tailored to suit any size air tool or planter, different openers, application rates, products, and row spacing for even and precisely targeted liquid applications.

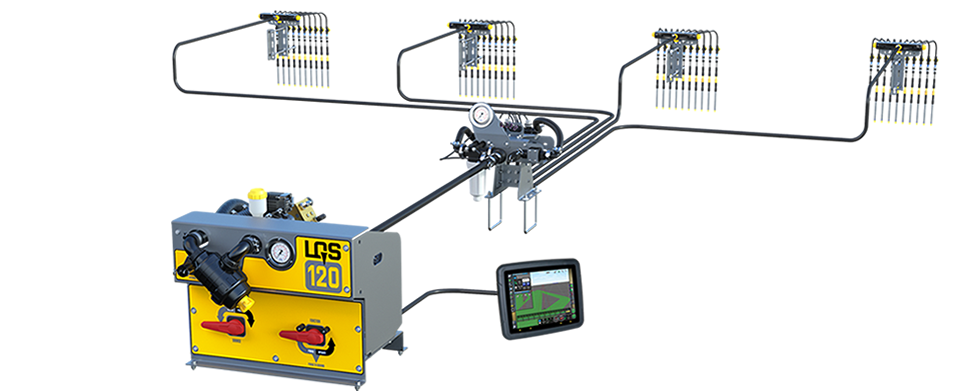

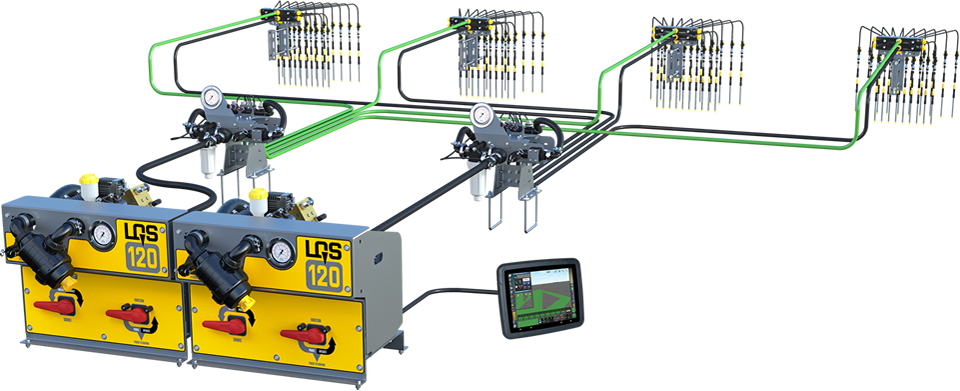

EASY UPGRADE to DUAL or multiple liquids

Upgrade or add a second module and liquid line whenever you’re ready! Our LQS “Goldline” hydraulic flow block enables multiple pump modules to run in series, while our “Stacker” manifolds allow for easy addition of manifolds and terminals to an existing Stacker system for separate, targeted liquid streams.

Single

Dual

LQS MODULE RANGE

Wide or narrow implements, high or low application rates, big or small tanks, all with adequate agitation, the LQS range has got it covered.

LQS “Goldline” Hydraulic Flow Block

The new “Goldline” hydraulic flow block improves flexibility with:

- Easy daisy-chaining of additional modules for multiple liquids and chemical injection.

- Individual pump speed set for each pump. Reduce pump output for low flow rate / low agitation product applications.

- Any pump module in the series can be simply deactivated with the turn of a knob when not required for specific cropping operations.

LQS FSO (Fast Shutoff) Valve Set

The new LQS single valve FSO (Fast Shutoff) Valve Set delivers:

- Simplicity and improved reliability with less moving parts. The one valve provides flow control and master on-off functions.

- Flexibility – the one valve set configuration suits Single Swath and Section Control configurations – making it easy to add Section Control at a later stage.

-

Improved responsiveness* for variable rate application. (*for many but not all makes of rate controller)

FEATURES

- Precision rate control valve set incorporating fast shutoff regulating valve and flowmeter

- Module mounted pressure gauge

- Pressure transducer & pump speed sensor for on-screen monitoring

- Suction filter

- Front panel controls for fertiliser/clean water tank selection & function selection (operate, purge, dump)

- Prescription map variable rate control when integrated with many Precision Ag control systems

- Section control compatible

- Robust, chemical resistant components

- Tank plumbing kit included

- Compact module design

BENEFITS

- Input use efficiency with section control, variable rate application and improved rate control responsiveness

- Target inputs in-furrow with measured and controlled placement in the soil

- Ease of installation – Compact module design, all-in-one complete kit

- Easy upgrade to section control, multiple liquids or chemical injection

- Input synergies with multiple independently controlled liquids

- Improved range – to accurately control flow rate to cater for variable rate application, variations in operating speed and shutting off sections automatically

- Reliable operation & equipment longevity

- Safe product application – no damage to liquid products – keep microbial products alive

- Ease of liquid handling & storage over granular or anhydrous – operational efficiency & safety

- Accurate “as applied” input data collection

Get a Quote

"*" indicates required fields