Row to Row Accuracy

Liquid Systems’ engineered “STACKER” Kit delivers a multitude of liquid inputs with “Row to Row, Second by Second Accuracy” by means of positive controlled pressure all the way to the openers. This accuracy and even distribution is critical for crop protection success.

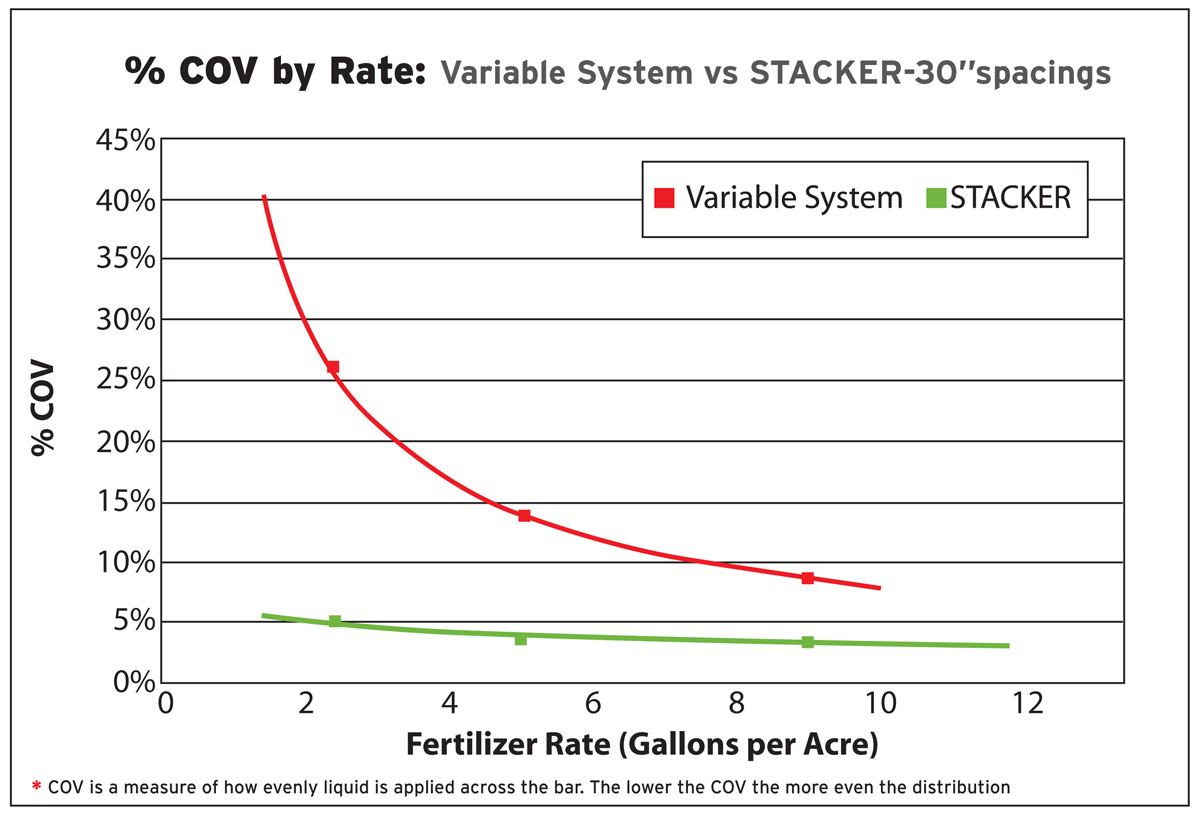

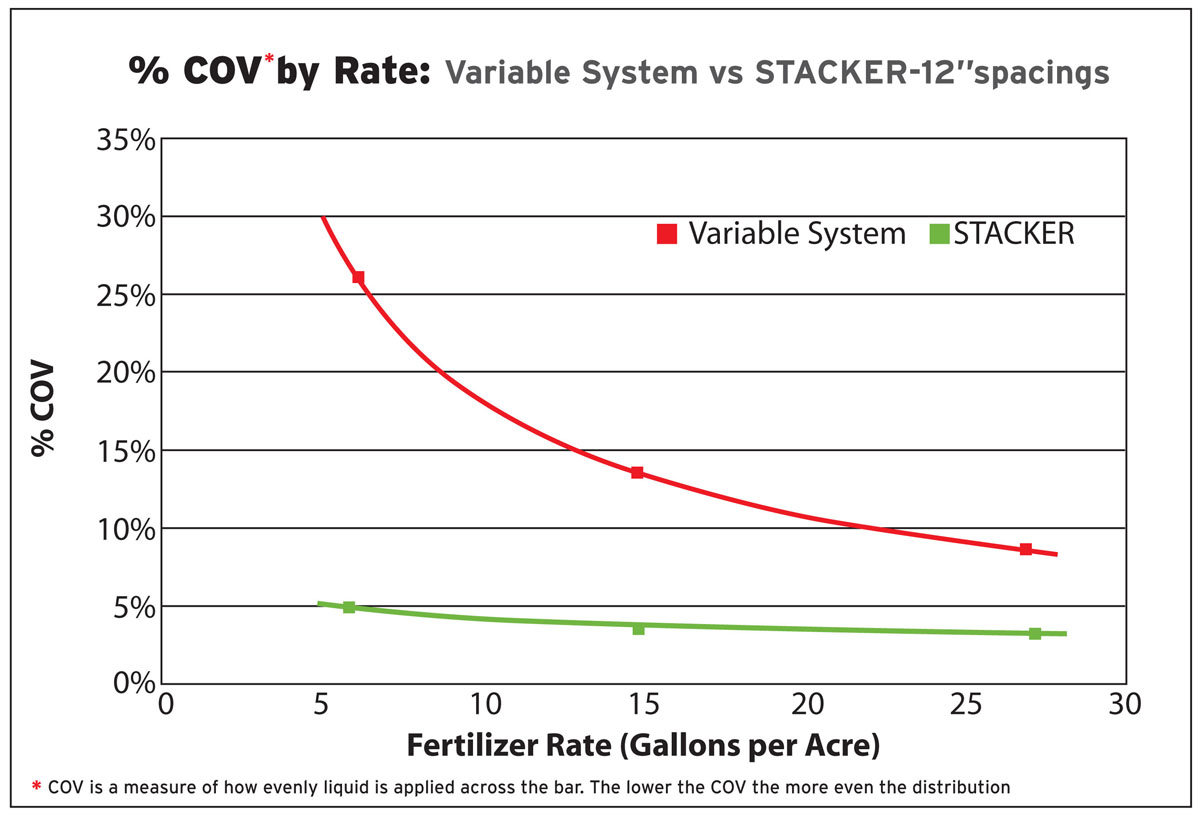

GRAPHS BELOW – SEE THE GREEN LINE: Show that customers can be confident that every row of their crop will receive the target liquid application rate evenly distributed in the furrow.

| Coefficient of variation (COV) Graphs |

|---|

Independently conducted testing by a US customer has demonstrated that Liquid Systems (SA) “STACKER” Kit has superior performance against a commonly used variable flow system. The graphs compare the Coefficient of Variation (COV) of the two systems:

- The first chart is at 12” spacings. The second chart is at 30” spacings.

- COV is a measure of how evenly liquid is applied across the bar. The lower the COV the more even the distribution.

- The results demonstrate an extreme contrast in accuracy between the two, especially at lower rates. The “STACKER” Kit provides a far superior performance with a verified average COV of 4.1% over an operating pressure range of 0.3bar – 7.0bar (4.5psi – 100psi) across a wide range of application rates.

Accurate in-furrow delivery is essential to reduce input costs to the farmer while maximising the benefits of their inputs.

There is simply no point in applying liquids unless you do it accurately! Under apply product and you’re ineffective, over apply product and you’re wasting money, fracture your streams and you can forget about applying fungicides and inoculants via injection

Peter Burgess, CEO & Founder of Liquid Systems (SA)I apply inoculant using the Liquid System at planting and not only am I coating the seed but I’m inoculating my ground as well. This gives the seed the most perfect little world to germinate in and it works remarkably well. I can’t describe how happy I am about that part of the system – it just works so well.

Lee Lonergan, Mungindi, NSWThe level of accuracy and consistency that the Liquid Systems equipment provides also means you’re not wasting product

Andrew Hansen, Coomandook, SAMore inputs at seeding for less cost, through my Liquid System, means more dollars back in my pocket

Michael Shepley, Yorkes, SAThe system was beautifully presented, very easy to install & worked brilliantly.

Ross Fisicaro, Warragoon, NSWI’m very happy with the performance of our a-i and the support provided by Liquid Systems (SA). I’m particularly impressed with the quality of their products

Andrew Longmire, Salmon Gums, WAI used the dual pump system this year with very pleasing results. I put liquid nitrogen and some phosphate over 4000Ha and found this system very accurate, reliable and able to stand up to all I asked of it

Trevor Walters, Manangatang, VIC