Terminal Tube

Custom Polyethylene Alloy Tubing

Our tubing is custom-extruded to exact tolerances, engineered for UV stability, flexible and tough enough to bend into tight radii without crushing. Available in a range of terminal and delivery sizes for accurate rate selection and installation flexibility.

-

Durability & Longevity – Withstands extreme weather, UV exposure, and agricultural chemicals.

-

Impact Strength – Tough enough for rough handling and impacts.

-

Wear Resistance – Superior abrasion resistance.

-

Chemical Resistance – Maintains integrity under prolonged chemical exposure.

These are a part of the unique Stacker Distribution System and are found in the various Terminal Configurations.

Description

| Tubing Variations | |

|---|---|

| 5.0mm OD X 1.2mm ID (Yellow Friction Tube) |

ORDER CODE: L08120 This FIBP (Friction Induced Back Pressure) tube has been specially developed for utilisation with high viscosity / hard-to-handle liquids and ultra-low rate application regimes. Included in terminal configurations LQS-AT5F |

| 5.0mm OD X 1.5mm ID (Pink Friction Tube) |

ORDER CODE: L08119 This FIBP (Friction Induced Back Pressure) tube has been specially developed for utilisation with high viscosity / hard-to-handle liquids and ultra-low rate application regimes. Included in terminal configurations LQS-AT5PKF |

| 5.0mm OD X 1.8mm ID (Grey Friction Tube) |

ORDER CODE: L08118 This FIBP (Friction Induced Back Pressure) tube has been specially developed for utilisation with high viscosity / hard-to-handle liquids and ultra-low rate application regimes. Included in terminal configurations LQS-AT5GF |

| 5.0mm OD X 2.5mm ID (Black & Yellow stripe) |

ORDER CODE: BL-204390 The 5.0mm has been introduced to facilitate easier system installation and maintenance on our air seeder systems. The bore size of this tube provides good stream control and eliminates the requirement for terminal jets. Included in terminal configurations LQS-ATST, LQS-PTST) |

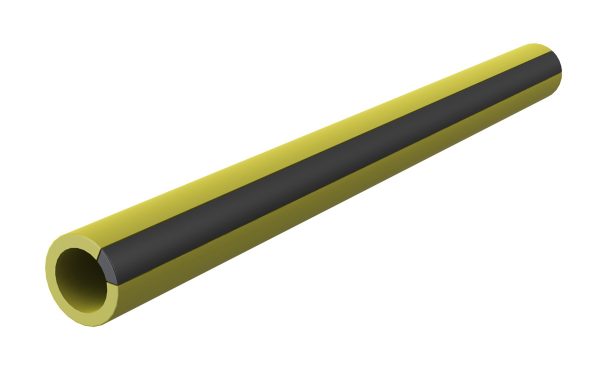

| 6.0mm OD X 4.2mm ID (Yellow & Black stripe) |

ORDER CODE: BL-204396 The 6.0mm tube is being introduced specifically as a dealer sourced retro-fit for planters. It is a push-fit and passes through the larger 12.75mm X 10.0mm stainless steel opener tubes that are common to these units. This tube size permits rates up to 38 US GPA at 30” row spacings to be applied while still delivering good stream profiles at low application rates — (essential if clients are contemplating applying inoculants, fungicides etc. via furrow injection). (Included in terminal configurations LQS-PTHR) |

| 8.0mm OD X 5.2mm ID (Black & Yellow stripe) |

ORDER CODE: BL-204402-08 8.0mm Delivery Tube. (Included in ALL manifold configurations) |

| 10.0mm OD (Black) |

ORDER CODE: JG-PE-1007-100m-E This 10mm tubing is for Strip-Till. Included in terminal configurations LQS-ST |

| Features: |

|