Why we don’t use Centrifugal Pumps for in-furrow liquid application

At Liquid Systems (SA), we recognize the extraordinary developments in the areas of plant nutrition and crop protection that is occurring.

Many of the wide and varied range of liquid nutrients, crop protection products and bio-stimulants now available can be applied in the furrow with or in proximity to the seed. The method of application often gets overlooked, but we see it as a critical part of the equation.

We understand this creates a requirement for effective equipment for in-furrow application of these liquid formulations.

Care with respect to temperature and system pressure when injecting live microbial products is of prime importance! Microbial and other liquid products can be prone to physical breakdown if not applied with suitable equipment, reducing or in some cases completely negating their effectiveness.

Not all liquid application systems are suitable.

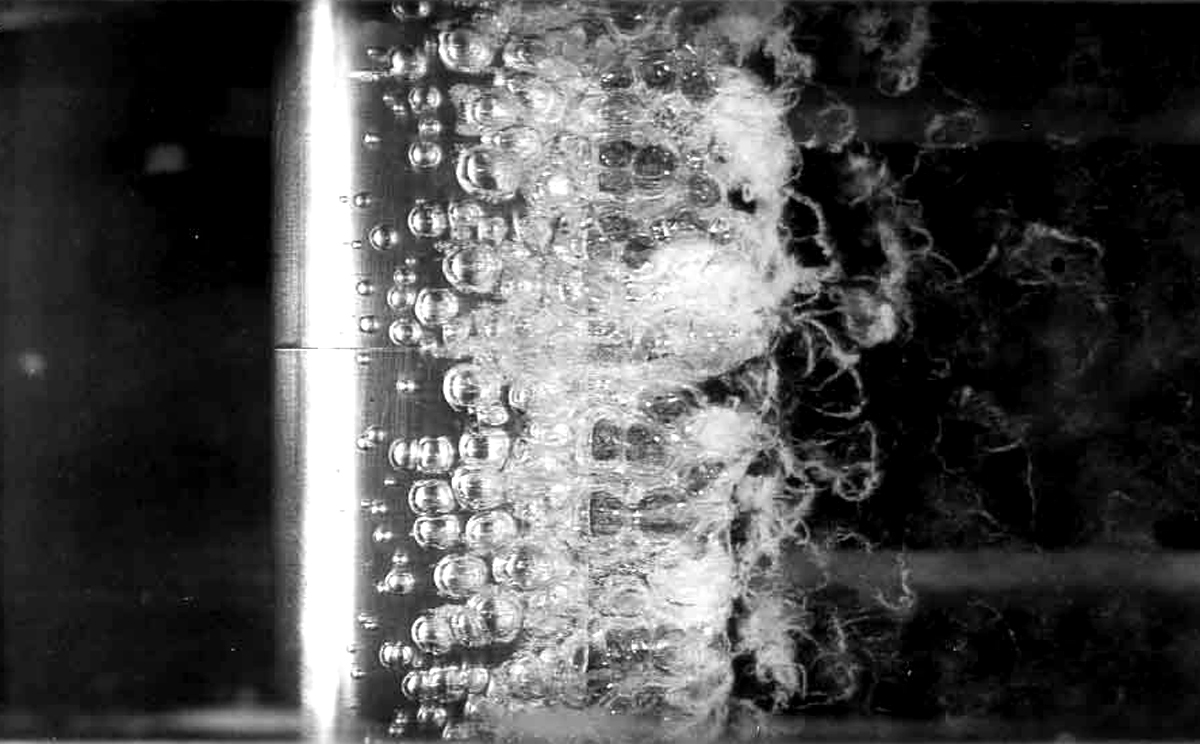

Cavitation is a phenomenon that occurs in centrifugal pumps. It is to be avoided at all costs as it can destroy chemical and physical properties of a liquid. If the liquid contains live inoculum they will die, either by pressure or heat!

Centrifugal pumps can cause liquid to boil in the pump. Systems using centrifugal pumps typically use a throttling device, to provide a useful operating range. Essentially the pump is a turbine running at high revolutions so as to provide a workable pressure range, but at the low application rates required for in furrow application, much of the liquid circulates inside the pump. Liquid flows between the impeller and the housing at very high velocity, increase the liquid temperature and can create a vacuum at the housing wall, causing liquid vaporization and formation of gas bubbles – cavitation.

We have witnessed systems in operation using such devices where the pump casing was so hot it was steaming! This is not a desirable trait for delivery of live inoculum or any liquid.

When liquid is used in low volume in-furrow application, liquid will be recirculating through the pump for hours compared to a sprayer centrifugal pump, as the liquid is output at a much higher rate and are in the pump for a much shorter time.

Some products can have incompatibility issues, such as live inoculum being introduced via the wrong carrier. Always talk with your product supplier and your agronomist for advice.