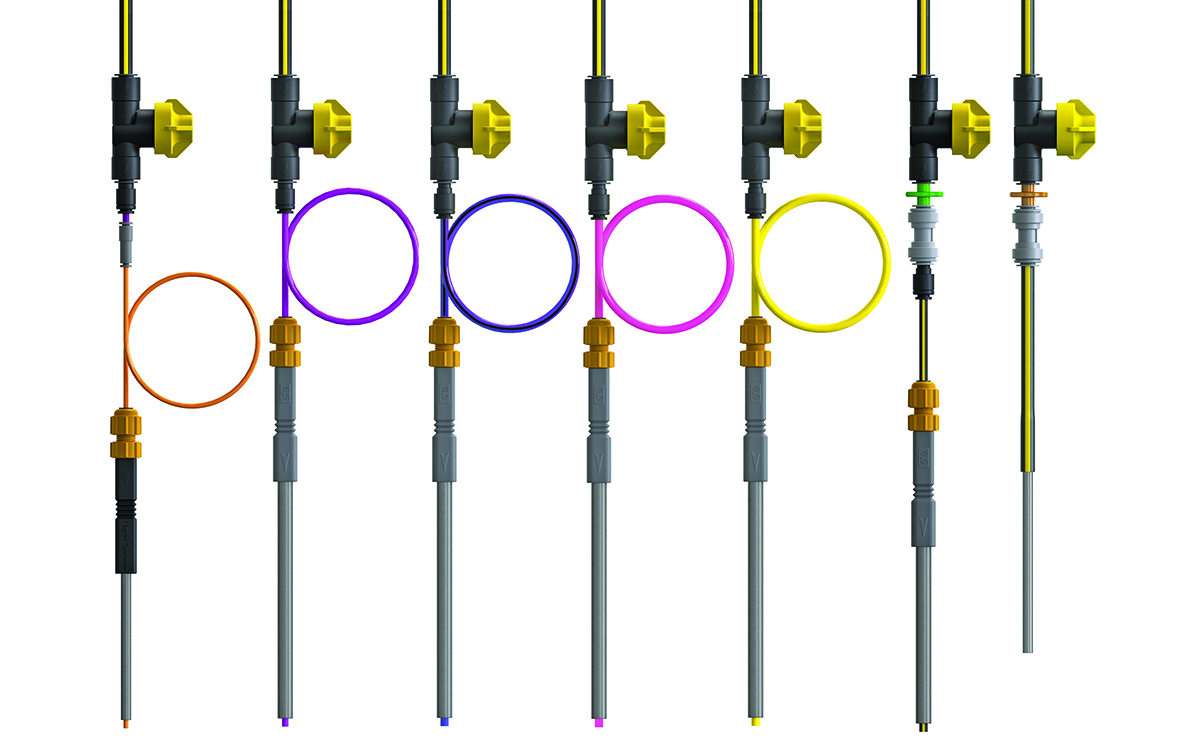

Terminal Assemblies – Friction Tube or Line Meters

AIR TOOL – TERMINALS

Liquid Systems has a number of Terminal Configurations for liquid distribution setups on air seeder tillage bars and planters. With Air Tool Terminal Configurations, the line from each manifold outlet can be split into two separate delivery lines. All Planter terminal configurations include in-line check valves for quick shut-off and start-up and a range of line meters. All connections are push-fit for simple assembly and maintenance.

Which restrictive device should i use? line meters or friction tube? Go to the Application & Resistance Charts HEREDescription

| Air Tool – 5mm x 1.2mmID Friction Tube |

|---|

ORDER CODE:LQS-AT5F

- 8mm Tees to split flow from manifold

- 8mm Delivery Tube

- Inline Check Valve

- 8-5mm Stem Reducer

- 5mm OD x 1.2 ID Yellow Friction Terminal Tube

- Line Locker

- V5 6.5mm Rubber Union

- Fits to 3/8” (9.53mm) OD x 1/4” (6.27mm) ID stainless steel delivery tube (not included).

Permits large bore. Ultra-low to high application range. Ability to apply difficult materials.

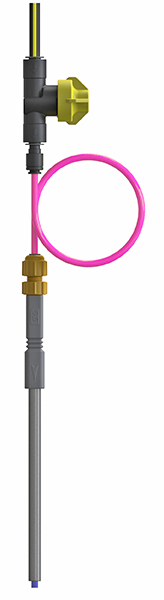

| Air Tool – 5mm x 1.5mmID Friction Tube |

|---|

ORDER CODE: LQS-AT5PKF

- 8mm Tees to split flow from manifold

- 8mm Delivery Tube

- Inline Check Valve

- 8-5mm Stem Reducer

- 5mm OD x 1.5 ID Pink Friction Terminal Tube

- Line Locker

- V5 6.5mm Rubber Union

- Fits to 3/8” (9.53mm) OD x 1/4” (6.27mm) ID stainless steel delivery tube (not included).

Permits large bore. Ultra-low to high application range. Ability to apply difficult materials.

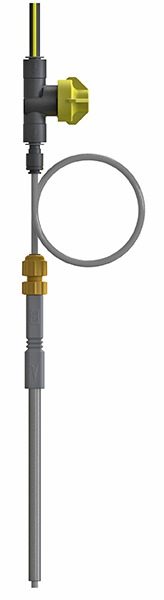

| Air Tool – 5mm x 1.8mmID Friction Tube |

|---|

ORDER CODE: LQS-AT5GF

- 8mm Tees to split flow from manifold

- 8mm Delivery Tube

- Inline Check Valve

- 8-5mm Stem Reducer

- 5mm OD x 1.8 ID Grey Friction Terminal Tube

- Line Locker

- V5 6.5mm Rubber Union

Fits to 3/8” (9.53mm) OD x 1/4” (6.27mm) ID stainless steel delivery tube (not included).

Permits large bore. Ultra-low to high application range. Ability to apply difficult materials.

| Air Tool – Standard – Line Meter |

|---|

- 8mm Tees to split flow from manifold

- 8mm Delivery Tube

- Inline Check Valve

- Line Meters (choose 3 sizes included)

- 8-5mm Stem Reducer

- 5mm OD x 2.5mm Terminal Tube

- Line Locker

- V5 6.5mm Rubber Union

- Fits to 3/8” (9.53mm) OD x 1/4” (6.27mm) ID stainless steel delivery tube (not included).

Good stream control across a wide range of application rates. For openers spaced 9”-15”.

| Air Tool – High Rate – Line Meter |

|---|

- 8mm Tees to split flow from manifold

- 8mm Delivery Tube

- Inline Check Valve

- Line Meters (choose 3 sizes included)

- 8mm Terminal Tube

Fits to 1/4” (6.35mm) OD stainless steel delivery tube (not included).

Suited for high rate applications or points with ¼” liquid delivery tubes.

PLANTER – TERMINALS

Liquid Systems has 2 different terminal assemblies for liquid distribution setups on planters. With Planter Terminal Configurations, each manifold outlet connects to an individual delivery line. All terminal configurations include inline check valves for quick shut-off and start-up and a range of line meters to suit the target application rates. All connections are push-fit for simple assembly and maintenance.

Refer to Flow & Resistance Charts HERE

| Planter- Standard – Line Meter |

|---|

- 8mm Tees to split flow from manifold

- 8mm Delivery Tube

- Inline Check Valve

- Line Meters (choose 3 sizes included)

- 8-5mm Stem Reducer

- Line Locker

- V5 6.5mm Rubber Union

- 5mm OD x 2.5mm Terminal Tube

Fits to 3/8” (9.53mm) OD x 1/4” (6.27mm) ID stainless steel delivery tube (not included).

Good stream control across a wide range of application rates. For openers spaced 9”-15”.

| Planter – High Rate – Line Meter |

|---|

- 8mm Tees to split flow from manifold

- 8mm Delivery Tube

- Inline Check Valve

- Line Meters (choose 3 sizes included)

- 8-6mm Stem Reducer

- Line Locker

- V5 6.5mm Rubber Union

- 6mm OD x 4.25mm Terminal Tube

Fits to 3/8” (9.53mm) OD x 1/4” (6.27mm) ID stainless steel delivery tube (not included).

Suitable for high rate applications.

STRIPTILL – TERMINAL

Strip-till Converged Stream Terminal Configuration

Designed for dual liquid high and low rate application at high operating speeds. Streams converge and are injected through a CNC machined nozzle. Ultra high rate channel is checked on the low rate channel to neutralise possible back-pressure issues associated with high volume convergence. All fittings are push-in. Oversize bulkhead push-in adaptor facilitates adaptation to coulter apparatus.

See other related products below for more Strip Till Configuration options.

| Strip Till |

|---|

- 8mm Tees to split flow from manifold

- 8mm delivery line

- 2 inline check valves

- non return valve

- line meters (choose 5 sizes included)

- 10-8mm stem reducer

- two way equal joiner

- strip till terminal jet

- V3 rubber union

- 10mm OD terminal tube

- CNC machined nozzle

For application rates from 2 to 50 GPA