John Deere C650 Liquid Ready Fert Kit

ORDER CODE: LQS120-C650TBH

ORDER CODE: LQS120-C650TBT

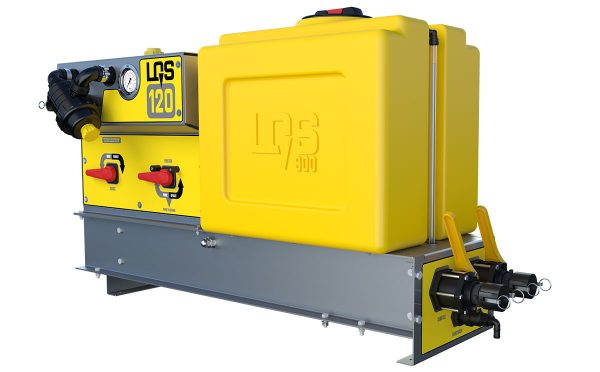

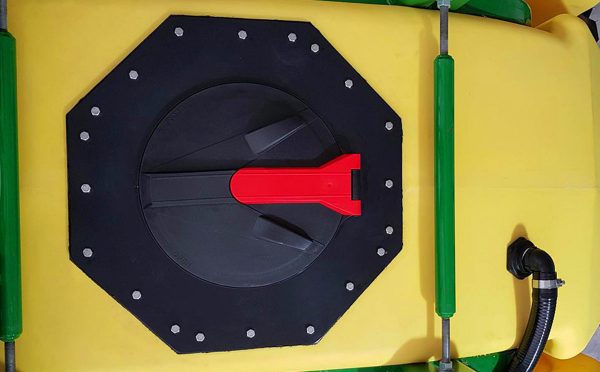

The new John Deere TBT & TBH C650 Air Carts have a liquid ready option with a dedicated centre (4581 L) liquid tank for the application of liquid fertilisers and crop care products.

Liquid Systems (SA) will supply the dealer fit Liquid Ready Fert Kit to John Deere dealers to install on C650 Air Carts before delivery to the farmer.

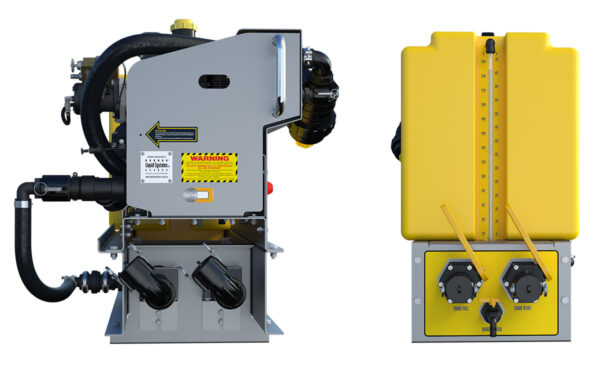

The LQS120 C650 Liquid Ready Fert Kit includes everything required to add liquid functionality to the C650 cart. It comes in two different configurations, one for the TBT and one for the TBH, with mounting assembly and hose kits tailored to each cart type.

Contact your John Deere Dealer Today! GO TO CUSTOMER CASESTUDY

Description

| Specifications | |

|---|---|

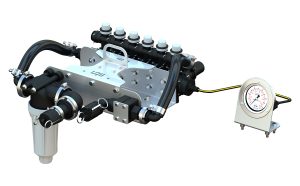

| Function: | High Volume Single liquid rate control |

| Max. Output: | 126 L/min 33 Ga/min (US) 27.7 Ga/min (Imperial) |

| Dimensions: | W 2130mm x D 1000mm x H 1100mm |

| Weight (dry): | 230kg (Module, 300Lt Tank & Base) |

| Pump: | Hydraulically driven positive displacement piston diaphragm pump |

| Hydraulic Flow: | 27.5 L/min 7.3 Ga/min (US) 6.0 Ga/min (Imperial) |

| Electrical 12V DC: | Single Swath – 2A Section Control (8 Sections) – 6A |

| Features: |

|

| Benefits: |

|