Reliability second to none.

A decade after adopting a liquid injection system, one Victorian farming family continues to reap the benefits with more timely sowing, improved plant health and crop yields.

Liquid injection systems have been an integral part of the Corcoran family’s potato and cropping operation for over a decade. Their recent purchase of two additional Liquid Systems modules is delivering improved efficiency and reliability.

| ABOUT |

|---|

- WHO: Peter Corcoran

- LOCATION: Bannerton, Victoria

- INPUTS: Fungicide, insecticide and bio-stimulant sprayed on the furrow and a separate stream of pop-up fertiliser in the furrow.

- PROPERTY: 480 ha potatoes, 1400 ha cereals

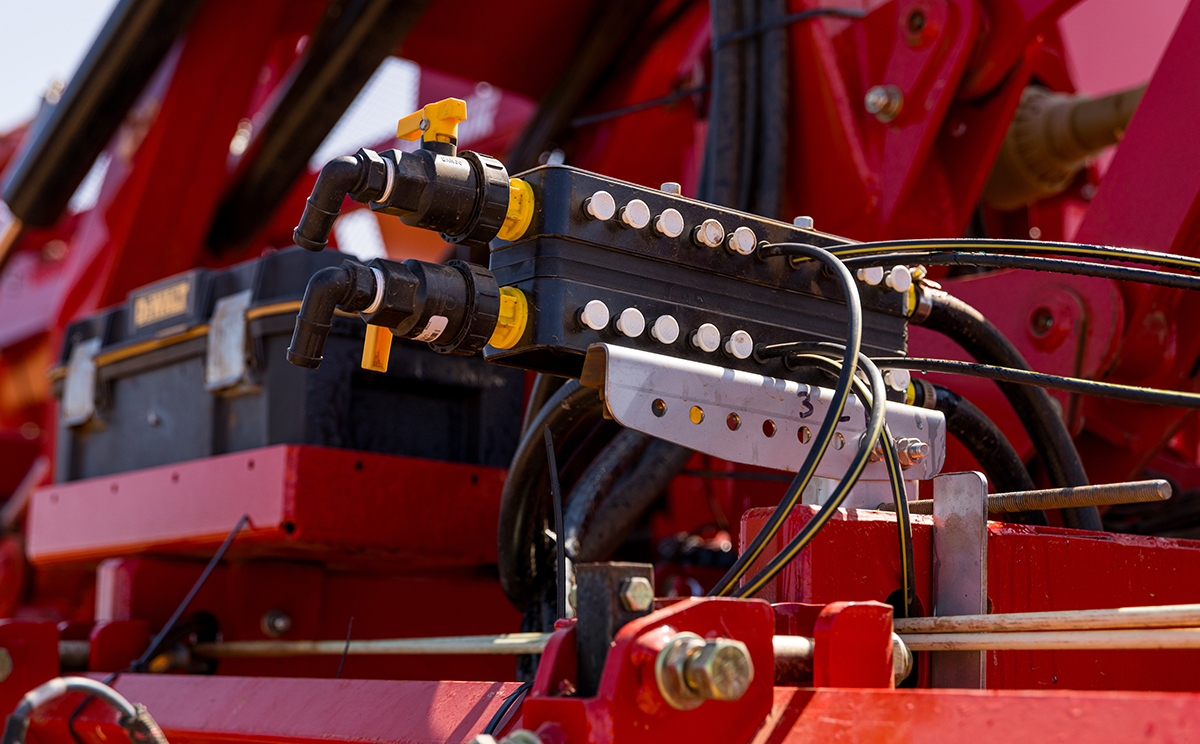

- EQUIPMENT: 2 X Liquid Systems (SA) LQS20 Module, Dual Stacker Kit, 12m Spudnik Planter

| KEY OUTCOMES |

|---|

- Long-term reliability

- Up Front Disease protection

- Improved plant health and crop yields

- Efficiencies of the sowing operation with more timely sowing

Peter Corcoran, a fourth-generation farmer from Robinvale in Northwest Victoria, runs Corcoran Farms, a family-owned potato, cropping and transport operation.

Having successfully adopted Liquid Systems (SA) Pump Modules and Stacker distribution kits on a previous potato planter and a cereal seeder, Peter says it was a logical step to stick with Liquid Systems technology when looking to upgrade.

“The reliability of these units is second to none. My first Liquid Systems unit lasted more than 10 years – and it’s still going,” Peter says.

The upgrade in 2024 included two LQS20 modules and twin 1800 L tanks mounted on a John Deere tractor, together with a dual stacker kit fitted to a Spudnik planter. Peter said the investment was partly driven by the desire to expand their liquid injection system to include liquid fertilisers, but also to achieve greater efficiency at planting time.

January here is very hot and we have limited days for planting so one of the aims of the new planter and the new twin liquid systems was to cover more ground per day

“January here is very hot and we have limited days for planting so one of the aims of the new planter and the new twin liquid systems was to cover more ground per day,’ he said.

Peter says the new Liquid Systems modules have proven to be effective in helping them achieve their goal of in-furrow application and overall, an efficient investment.

Before the upgrade, the Corcoran’s old system enabled a mix of fungicide, insecticide and bio-stimulant to be sprayed into the potato root zone during planting. Now with the new twin liquid systems, Peters says they can also inject a phosphorus-based pop-up fertiliser down the centre, with two potato rows on either side. Injecting phosphorus separately means higher rates can be applied without the headache of mixing and coagulation problems.

The Corcorans are seeing real gains from this approach, with healthier plants and more even germination. Peter says that applying the liquid mix directly into the furrow provides early disease protection and helps establish a strong root system. By delivering the treatment exactly where it’s needed, they’ve seen up to 90% less rhizoctonia and yield improvements of up to 10%

The upgraded system has also improved planting efficiency – with the 1800 L tanks, Peter can sow for most of the day without refilling – a significant improvement from their previous 1000 L setup.

Pleased with the ease of use and reliability of Liquid Systems equipment, Peter says the External Distribution Flush is his favourite feature, making it simple to test nozzles and flush at the end of the day. “This is my third and fourth Liquid Systems unit. I went straight back to them because I know the gear just works. Liquid Systems is well worth the investment. It’s reliable, and no downtime means dollars saved. I’d highly recommend it.