Precision Ag Integration (VRT) and Liquid Section Control

We started liquid section control back in 2010, it has been a slow burn but has become a popular choice in the last 5 years. Today, we see 60% of our new systems are bought with section control, however, section control can be added later if required.

Growers building confidence with liquid application have seen how implementing section control can deliver enormous efficiency gains in both land use and liquid product application, particularly with irregular-shaped paddocks.

With the price of farm inputs at an all-time high, precise application and section control can save costs during seeding. Delivering liquid inputs efficiently and accurately is now more paramount than ever.

READ HERE How Travis Stanley saved on his inputs

With our systems, we can implement up to 12 sections, dual or single swath and we offer a range of harnesses for ‘plug-n-play’ with most rate controllers on the market. Off-the-shelf adaptor looms are used as well as a range of ISOBUS control options.

The integration with a variety of precision systems enables advanced application features like section control and map/GPS-based variable rate application.

Variable rate application of other liquid products such as trace elements also provides greater efficiency for applications like treating deficiencies in the soil. Like fertiliser, these trace elements can also be applied across the paddock according to localised need rather than at a blanket fixed rate.

LEARN MORE HERE About Liquid Section Control

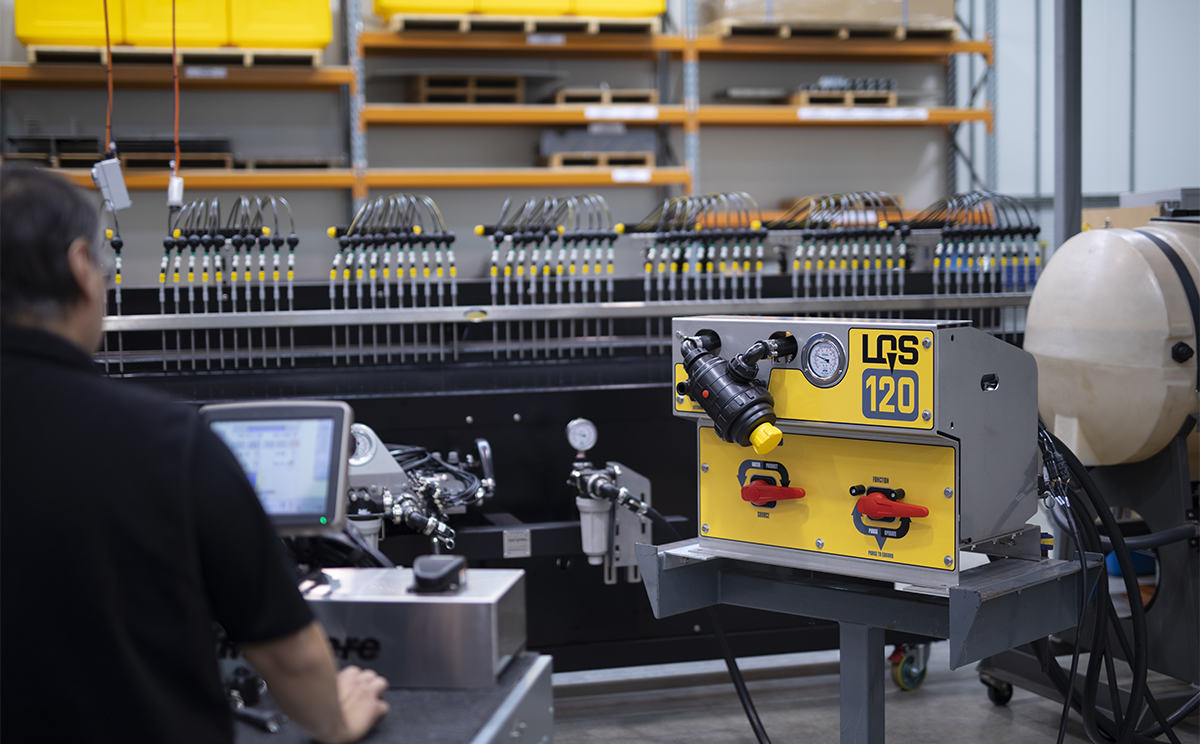

Photo Above: Patrick Whitfeld, Lead Electrical Engineer and Luke Hart, Precision Ag Specialist. Photo Below: Roy Tattoli testing a 6 Section Manifold

“This Year is our 20th Year of business and we have seen many different controllers come to market and it’s quite the job making sure we are up to date and having options for all old and new customers. Every year new models and updated software come out, so it’s an ongoing process to keep up”. Says Patrick Whitfeld, Lead Electrical Engineer.

We have the knowledge to support our products and if something really stumps us, we have our test facility to replicate what’s going on in the field

We take our quality assurance very seriously:

- Assembly Procedures

- Product quality Checklists

- Wet Testing of every module and harness before it leaves the factory

- Installation Manuals

- Controller Set up Guides

We have a team of committed and professional individuals that take great pride in delivering quality service and support to our customers. Please do not hesitate to call (08) 8357 4437

Photo Below: Every Liquid System is tested before it leaves the factory.

Get a Quote

"*" indicates required fields