Liquid Ready Fert Kit Design for the New John Deere C650 Air Cart

Two years in the making, two years a secret. Introducing the LQS120 C650 Liquid Ready Fert Kit.

In 2018 we were approached by a long-standing client, John Deere, to design & develop a Liquid Rate Control solution for the new C650 Air Cart to be released June 2020.

At 650 bushels, the new John Deere C650 Air Cart is much bigger than current 1910 models and is available with a Liquid Ready option. The C650 offers a liquid capable centre tank for growers who choose to incorporate liquid fertiliser into their seeding operations. While liquid fert kits are not factory-installed options, they are available through John Deere Dealer network.

We have been manufacturing and exporting in-furrow liquid application kits since 2002 all around the world and have worked with John Deere since 2010 with the first dealer-fit Liquid Ready Kit for the smaller 1910 Commodity Car. Consequently, we were engaged by John Deere to design the C650 liquid application solution and supply it as a ‘dealer friendly’ kit to John Deere dealers to install on C650 Air Carts before delivery to the farmer.

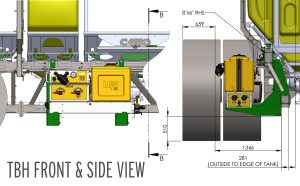

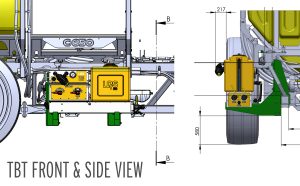

We commenced the project to design a liquid rate control module for the C650 Air Cart incorporating a pump & rate control module, clean water flush tank and tank fill station. Seamless integration of these 3 elements (both structurally and functionally) became a key feature of the design. The design brief also extended to dedicated support frames to mount the module to the two different cart chassis (tow-behind and tow-between) as well as streamlining connection lines (plumbing, hydraulic and electrical) to connect the module and add liquid application functionality to the cart, toolbar, tractor and Precision Ag systems.

IMAGES of Design & Testing Process:

Developing the Rate Control Module required us to operate within strict constraints set by John Deere. Achieving a high performing, compact product within these constraints was a design challenge treat for our team.

Such constraints included:

- only right-hand side of each cart was available for fitting the module

- no liquid specific modifications to the chassis allowed

- increased electrical power requirements of the cart itself and trailing toolbars

Researching and testing had already started on a single fast shut off valve system, the LQS “Next Gen” FSO Valve Set which uses a single three-way fast valve to perform regulating, master on/off and dump valve functions.

The new LQS ‘Goldline’ Hydraulic Flow block is another addition to the module. This allows users to easily add additional pump modules in series with independent control of the speed of each pump. Pumps can also be switched off individually when not required for the current seeding operation.

Transition to a single valve system and the new flow block has generated numerous technical and performance advantages for users:

- a module compact enough to fit within the mounting space constraints

- improved rate control stability & responsiveness

- improved range – to accurately control flow rate to cater for variable rate application, variations in operating speed and shutting off sections automatically

- a module that can be easily upgraded to output multiple independent liquids in one pass

- one module configuration that suits both single swath and section control application

Our team of Mechanical and Precision Ag expertise have been able to design, configure and test the electronic integration of the system to the John Deere Rate Controller 2000. We have also developed custom harness configurations to connect to electrical backbones of both the C650 TBH and TBT Air Carts. We also have an array of interface harnesses for adaptation to other leading brand rate controllers, both ISOBus and proprietary.

In May 2020, two years of research and development culminated with the first finished units fitted and installed for demo with minimal issues to the two different Air Carts. It was a great team effort working at two different dealerships in South Australia over a 6 day period. We would like to make special mention and thank John Deere’s Steve Quick for his support and hands-on approach. We also would like to thank Paul, Nicholas and Tanya Lush for their support and great images of the rig in the field.

For more information contact Contact your John Deere Dealer Today! or visit the Product Specifications Page

IMAGES of Roseworthy and Jamestown Install:

Get a Quote

"*" indicates required fields